Medical

- Medical

For 20 years, Industrial Metal Tubes has partnered with the world’s leading medical device manufacturers to engineer the highest quality tubes with optimum surface cleanliness, biocompatibility, strength-to-weight ratios, and grain structure.

These unique advantages enable medical devices to evolve towards smaller sizes, lighter weight, and promote osseointegration for improved quality of life.

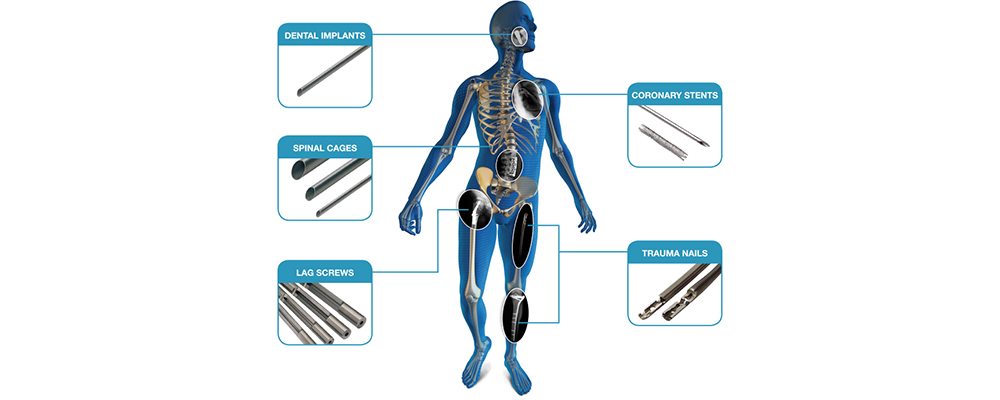

- Medical Tube Applications

- Trauma and orthopedic implants

- Trauma nails, screws, and lag screws

- Spinal cages and screws

- Dental implants

- Coronary and peripheral stents

- Endoscopy equipment and instruments

- Cannulas

- Light, Strong and Biocompatible Alloys

Choosing the best alloy for your medical application is key to having an optimized final product. Our experts work closely with customers to manufacture the exacting properties demanded. We don’t just set out to meet industry standards for tubular medical pre-materials, we aim to exceed them.

- Stainless steel , Titanium, Specialty (MP35N®, Nitronic® 50)

- Typical Manufacturing Standards

- DIN 17449 W-Nr 1.4401

- ASTM F136 1996 Ti6/4 ELI

- ASTM F138-00 316L/316LVM

- ASTM F1314 1995 22Cr-13Ni-5Mn

- ASTM F2063-00 - NiTi Shape Memory Alloys

- 21Cr 10Ni 3Mn 2.5 Mo

- ISO 5832-11 1994 BS7252: Part 11 - Ti 6Al 7Nb

- ISO DIN 25832-1 (Implants for surgery – seamless tubes for surgical implants - materials based on iron)

Copyright by 2024 INDUSTRIAL METAL & TUBES. All Rights Reserved || Designed By : Shraddhawebsoft